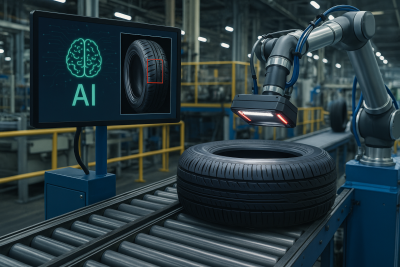

The tire manufacturing industry is undergoing a massive transformation driven by advances in automation and digital technologies. A key piece of this evolution is artificial intelligence (AI), which is reshaping the way manufacturers approach quality control. By integrating AI into production processes, tire manufacturers can now detect defects more accurately, streamline inspections, and reduce costly waste.

Why Quality Control Matters in Tire Manufacturing

Tires are a critical component of vehicle safety and performance. A single flaw can lead to major safety hazards, vehicle recalls, and damage to brand reputation. Traditionally, quality control in tire manufacturing relied heavily on manual inspections and physical testing. While effective to a degree, these methods are time-consuming, labor-intensive, and prone to human error. AI changes the game by bringing speed, precision, and consistency to the quality control process.

How AI Is Improving Tire Inspection and Defect Detection

AI-powered systems use advanced image recognition and machine learning algorithms to analyze visual data from tire production lines. These systems can detect anomalies such as sidewall imperfections, tread pattern inconsistencies, or internal structural issues in real time. Unlike manual inspections, which might miss subtle defects, AI can evaluate every tire with the same level of scrutiny—24/7 and without fatigue.

In addition to surface-level inspections, AI is also enhancing non-destructive testing techniques, such as X-ray and laser-based inspection systems. By learning from thousands of images and historical data points, AI can spot defect patterns and predict failures that might otherwise go unnoticed.

Predictive Analytics for Continuous Improvement

Beyond immediate defect detection, AI plays a vital role in predictive quality control. By analyzing trends in production data, AI can forecast when defects are likely to occur and suggest corrective actions before problems escalate. This proactive approach minimizes downtime, improves product consistency, and helps manufacturers optimize their processes over time.

Challenges and Considerations

While AI offers significant benefits, its implementation requires a thoughtful strategy. High-quality data is essential to train AI systems effectively, and integrating AI with legacy manufacturing equipment can be complex. Additionally, companies must invest in employee training to ensure teams can work alongside AI systems and make the most of the insights they provide.

While AI offers significant benefits, its implementation requires a thoughtful strategy. High-quality data is essential to train AI systems effectively, and integrating AI with legacy manufacturing equipment can be complex. Additionally, companies must invest in employee training to ensure teams can work alongside AI systems and make the most of the insights they provide.

Looking Ahead

As the tire industry continues to evolve, the role of AI in quality control will only expand. Manufacturers that embrace AI today are better positioned to meet growing demands for safer, more reliable, and more sustainable tires. With smarter systems in place, they can not only catch defects faster but also prevent them before they happen—a true leap forward for tire manufacturing quality control.

At UMD Automated Systems, we specialize in designing and integrating custom automation solutions for tire manufacturers. From advanced inspection systems to complete production line automation, our team helps clients leverage emerging technologies to stay ahead in a competitive market. Contact us today to learn more about bringing the latest advances in manufacturing technology to your processes.